Copyright © 2022 Philip C. Cruver

Preface: I'm on a mission to change the colloquial nomenclature for "seaweed" to "seaplant" as "weed" has a pejorative connotation that usurps the positive branding message for this amazing regenerative and sustainable biomass.

Background

In 2021, I was retained as a consultant by the Inter-American Development Bank to develop a marketing and distribution strategy for seaplant exports from Belize to international markets. Prior to the pandemic, Belize's artisanal seaplant operations consisted of a handful of small farms producing about 6,000 pounds annually used in beverage shakes for the local tourism market. Interestingly, one of the seaplant farms was a cooperative owned and operated exclusively by women that had received positive publicity because of the recent movement for gender equality. The timing was providential for creating an export market exploiting the touchstones of social, gender, and environmental justice and jobs for a post pandemic devastated Belize economy based upon tourism.

Therefore, the targeted market for a Belize seaplant industry was determined to be high-value exports to the United States as a regenerative food ingredient for human consumption. There is a major potential market for sustainably traceable seaplants harvested from pristine ocean waters that could be branded as nutritious superfood. Seaplants have 92 of the 102 essential minerals required for strengthening human immune systems for healthy living. Furthermore, seaplants can double their biomass in two weeks for sequestering massive amounts of CO2 as a nature-based solution for the decarbonization of our planet.

I had previous experience with seaplants (California's Giant kelp) while serving as a Principal Investigator for the $25 million MARINER (Macroalgae Research Inspiring Novel Energy Resources) contract funded by the Department of Energy. However, that research project was focused on seaplants as a renewable biomass for biofuels for fueling the future. Belize's native seaplant Eucheuma is edible, which presented a new and exciting learning experience for feeding the future.

Commercial Development of Global Eucheumatoid Farming

The history of Eucheumatoid (Eucheuma and Kappaphycus) seaplant farming for specialty chemicals and its introduction to 40 or more jurisdictions across the globe is fascinating. Starting as experimental farming in the Philippines during the 1960s, Eucheuma and Kappaphycus gained commercial traction in the 1970s resulting in their introduction to other warm weather countries such as Indonesia and Tanzania. In most of these countries Eucheumatoids were not indigenous which would be controversial today. Also, these seaplants are finicky about temperature and sunlight and only do well as a farmed crop when grown within 20 degrees North and South of the Equator.

The impetus for introducing non-native seaplant feedstocks was market demand from hydrocolloid manufactures who desperately needed cultivated raw biomass sources for biochemical production in the 1960s. Eucheumatoid wild stocks were being depleted and demand for carrageenan (used for food processing) expanded rapidly before leveling off to about 250,000 metric tons by 2007.

Not counting China, Indonesia is the global seaplant leader followed by the Philippines for producing over 80% of the world’s carrageenan. Other countries include South Korea, North Korea, Japan, Malaysia, and India. Zanzibar, located 18 miles off the coast of Tanzania, is also a major producer employing about 25,000 farmers, of which about 80% are women for exporting 15,000 metric tons annually.

In all these countries seaplants are cultivated using traditional methodologies including the fixed, off-bottom line method, the floating raft method, and basket method. Remarkably, the massive seaplant industry has remained artisanal despite explosive growth.

Carrageenan, extracted from red seaplants such as Eucheuma, is used as a thickening, emulsifying, or suspending agent in the food, chemical and pharmaceutical industries. The worldwide market for carrageenan was valued at $1.6 billion in 2020 and is expected to reach $3 billion by the end of 2026, growing at a CAGR of 9.6% during the forecasted period.

Hydrocolloids, also extracted from seaplants are used in the functional food industry as thickeners, stabilizers, coagulants, and salves (in the wound and burn dressings) and as materials to produce bio-medical impressions in the food, pharmaceutical, and biotechnology industries. The global hydrocolloids market was valued at $9.7 billion in 2020 and is projected to reach $13 billion by 2026, at a CAGR of 5.4% during the forecast period.

How can the hydrocolloid industry meet the massive projected demand in five years employing impoverished artisanal laborers without modern seaplant farming methods for assuring quality control and a resilient supply chain? In my opinion, the industry must be reimagined with innovative technologies that are sustainable and scalable for producing higher paying "Blue Jobs" that promise social, gender, and environmental justice for the future.

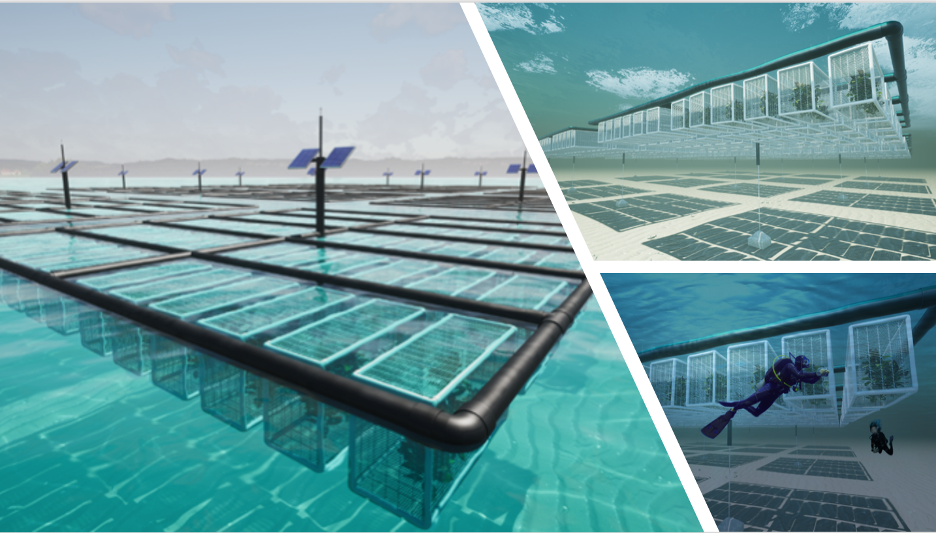

While it is astonishing that there has been no technological advances over the past two decades for improved, more modern farming methods, the recent research report "Floating Cage: A New Innovation of Seaweed Culture" published in 2020 provides promising data for seaplant cultivation in Indonesia. Using cages suspended from PVC floating rafts, having multifilament netting, produced a 54.9% increase in Eucheuma growth in 40 days as compared with traditional long line cultivation. The specific growth rate increased to 6.4% per day using the floating cage in Indonesia and hopefully the global industry will adopt this method of cage cultivation with further improved features for meeting the challenges of expanding offshore and the abiotic perils caused by climate change.

Submersible Seaplant Structures

In 2010, KZO Sea Farms developed a submergible cage for fish farming with engineering support from the School of Marine Science and Ocean Engineering at the University of New Hampshire and ISCO Industries, the largest HDPE fabricator and distributor in North America. See tabs "Mariculture Parks" and "News" at www.kzoseafarms.com for cage images.

We reconnected for designing a Submersible Seaplant Structure constructed with High Density Polyethylene (HDPE) pipes. The unique and innovative design provides four transformative benefits for seaplant mariculture:

1) The buoyant HDPE pipes can be filled with seawater by opening valves submerging the structure for protection from storms and hurricanes.

2) The submersible capability allows the structure to be positioned in the ocean water vertical column having optimum cultivation characteristics for producing significantly higher crop yields.

3) The technology employs cage culture for protecting seaplant crops from losses due to pest predation, epiphyte attachments, and storm shocks. Traditional long line culture is vulnerable to storm breakage whereby the crops are washed away by the current. Submersible cage culture also helps to protect the crops from ice-ice disease that infects long line cultivation. This is attributed to summer surface water heat and monsoon freshwater salinity changes causing stress and bleaching.

4) The proprietary features facilitate an innovative farming, monitoring and distribution system that is traceable to the cage a seaplant was grown and the day it was harvested for transparently meeting sustainable certification standards.

The technology has monitoring sensors for recording sunlight, current, salinity, and temperature. These factors are critical for seaplant growth and survival, and the structures can be moved to more favorable locations attributed to variable seasonality changes and other influencing abiotic factors.

Research reveals that the future for a commercial seaplant industry will be expanding farming operations offshore to deeper waters not conflicting with coral reef ecology, ocean tourism, and fisheries. Furthermore, offshore mariculture will help mitigate theft and vandalism. Moreover, offshore depths provide the ability to submerge to cooler and more nutrient-rich waters based upon seasonality and a changing thermocline from global warming.

Most importantly, the submersible technology is essential for protection from storms, typhoons, and hurricanes which are predicted to increase with climate change. With a few days’ notice, HDPE pipes can be filled with seawater lowering the structure to a depth that has an exponential decrease in ocean energy from storm winds and currents.

Seaplant Mariculture 4.0

This primitive seaplant industry is ripe for disruption for feeding and fueling the future. Recent collaborative R&D between academia and the mariculture industry are leading to new technologies and innovations for improving the efficiency and productivity of seaplant farming systems and for making them more eco-sustainable and appropriate for the emerging blue economy.

Submersible Seaplant Structures would produce higher crop yields and provide protection from predators such as rabbitfish, turtles, and long-spine sea urchins as well as storm damage from typhoons in tropical regions. Furthermore, the technology would provide traceability data on when and where the seaplant crops were harvested for meeting rigorous sustainability standards.

There is a huge opportunity for developing strategies and technologies to reduce fouling issues and identify solutions for determining optimal stocking density and photon fluence levels. There is also a major opportunity to develop novel seaplant strains that are more sunlight and thermally tolerant and epiphyte disease resistant. The abiotic factors such as light, temperature, salinity, and nutrient concentration greatly influence the composition of seaplants. Recent research shows the correlation between seaplant compound variation with abiotic factors such as UV radiation and salinity, and cultivation can be optimized by water depth selection to obtain a higher pigment yield with favorable exposure to solar radiation.

The massive ocean area is currently not a limiting factor for expanding offshore seaplant mariculture, but climate change with the consequential changes in water temperature and water chemistry could lead to a future reduction of suitable near shore cultivation areas. As a result, large scale seaplant operations may be required to move further out into the open ocean which will require innovations for enduring the challenges of the harsh open ocean environment. Thus, a new multidisciplinary level in the seaplant mariculture industry is emerging with an emphasis on biological sciences and engineering.